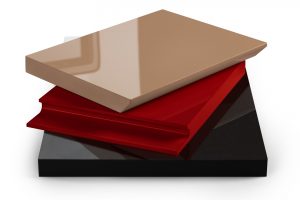

New Premium Acrylic

MAXIMUM SCRATCH RESISTANCE ON NON-LACQUERED SURFACES:

We have doubled the level of scratch resistance in comparison to the Quality Standard on the marketTHE BEST GLOSS AND MIRROR EFFECT ON THE MARKET:

It Means Quality (Not comparable to other technologies)THE WIDEST RANGE OF COLOURS:

More than 50 colours in the catalogue & Matching OptionOPTIMUM EDGE FINISHING:

Post-formable material enables the manufacturing of integrated handlesSERVICE AND FLEXIBILITY:

Shorter times and Smaller quantitiesENVIRONMENTAL RESPECT:

Recyclable, Non-toxicOPTIMAL UV AND CHEMICAL RESISTANCE:

Excellent level of colour stability against UV exposure and resistance to chemical agentsEASY TO PROCESS:

With standard carpentry machineryMAXIMUM SCRATCH RESISTANCE:

We have doubled the level of scratch resistance in comparison to the Quality Standard on the marketWith the launch of the new generation of the Premium Acrylic product by Plasnor, we have achieved maximum scratch resistance on non-lacquered acrylic surfaces, with double the scratch resistance compared to the standard quality on the market. Having removed the protective film and without the need to wait for a curing process to take place on the surface, the material attains the highest levels of scratch resistance. The different tests carried out in independent laboratories to verify scratch resistance (1.2N, 6H Pencil Test, 6mg Abrasion Test) confirm that the level of scratch resistance is much greater than the market standards of other non-lacquered acrylics.

MECHANICAL PROPERTIES

| CHARACTERISTICS | TEST METHOD | UNIT | VALUE |

|---|---|---|---|

| Scratch resistance | DIN 68861/T4 | N | 1,2 |

| Scratch resistance | Pencil Test | Visual | 6H |

| Abrasion resistance | DIN 53754 | mg/100U/min | 6 |

| Resistance of surface to mechanical damage | DIN 53799/T4.4.2 | mm | 7 |

This makes the quality of Plasnor´s Premium Acrylic finish perfect for vertical surfaces such as kitchen, wardrobe or connecting doors, panels, furniture, etc. Other acrylic materials with hard coating lacquered surfaces are not recommended for horizontal applications such as worktop, tables, etc.

Unlike lacquered finishes, the technology used to make the material more resistant enables it to be post-formed and provides better edge finishing. The joint of the sheet with the edge can be polished so that the joints are not noticeable, to achieve a perfect finish.

Additionally, Plasnor´s premium acrylic sheets can be polished to combat possible scratches due to impact. On the contrary, with hard coating lacquered surfaces it is not possible.

THE BEST GLOSS AND MIRROR EFFECT ON THE MARKET:

It Means Quality (Not comparable to other technologies) The extraordinary gloss and depth of the mirror effect of the Premium Acrylic sheets makes us stand out from other acrylic manufacturers and other technologies used in the furniture industry. In the tests that we carried out to measure the gloss of different colours they attain a gloss figure of close to -90 GLE and in some cases even better.

The extraordinary gloss and depth of the mirror effect of the Premium Acrylic sheets makes us stand out from other acrylic manufacturers and other technologies used in the furniture industry. In the tests that we carried out to measure the gloss of different colours they attain a gloss figure of close to -90 GLE and in some cases even better.

OPTICAL PROPERTIES

| CHARACTERISTICS | TEST METHOD | UNIT | VALUE |

|---|---|---|---|

| Top surface gloss | DIN 67530 | GLE | >85 |

The gloss of Premium Acrylic is synonymous with quality, luxury and exclusivity. A good finish is key in order for the furniture or board to transmit these properties.

The mirror effect, which consists of the perfect definition of the reflected object, is superior to that of any other technology. This is one of the main reasons why our clients choose the Premium Acrylic sheets.

The mirror effect, which consists of the perfect definition of the reflected object, is superior to that of any other technology. This is one of the main reasons why our clients choose the Premium Acrylic sheets.

Traditional lacquer, PVC, PET and UV lacquer are used to achieve finishes that add gloss to surfaces, but they do not achieve either the depth or the definition of the mirror effect of acrylic sheets. A perfect surface finish is essential to avoid imperfections and the orange skin effect that is very visible on glossy surfaces.

THE WIDEST RANGE OF COLOURS:

More than 50 colours in the catalogue We currently have the widest range of colours on the market for acrylic sheets. Our range of products includes 50 solid and metallic colours in gloss and 8 colours in matt. Additionally, Plasnor is a market leader for Designs and Imitations of high-gloss acrylic. In recent years, Plasnor has developed an exclusive and innovative range of more than 20 designs such as woods, textiles, ceramics and geometric patterns, as well as more technical finishes such as brushed aluminium.

We currently have the widest range of colours on the market for acrylic sheets. Our range of products includes 50 solid and metallic colours in gloss and 8 colours in matt. Additionally, Plasnor is a market leader for Designs and Imitations of high-gloss acrylic. In recent years, Plasnor has developed an exclusive and innovative range of more than 20 designs such as woods, textiles, ceramics and geometric patterns, as well as more technical finishes such as brushed aluminium.

Recently, Plasnor launched a new collection of 10 colours following the trends of the main markets and international manufacturers. Revamping the catalogue of colours and following the trends and fashions of the leading markets in the furniture industry is essential to satisfy the needs of the most demanding clients.

Recently, Plasnor launched a new collection of 10 colours following the trends of the main markets and international manufacturers. Revamping the catalogue of colours and following the trends and fashions of the leading markets in the furniture industry is essential to satisfy the needs of the most demanding clients.

Plasnor also has its own laboratory and the manufacturing of colour concentrate or Masterbatch. This enables optimum control of colour stability and means that we are able to carry out matching, either through PANTONE or RAL or a physical sample.

OPTIMUM EDGE FINISHING:

Post-formable material, it enables the manufacturing of integrated handles- The ABS/PMMA Premium Acrylic sheets are post-formable and enable and optimal technical finish of edges.

- Unlike lacquered sheets (hard coating), they enable traditional post-forming at 90ºC.

- With this material it is possible to manufacture integrated K Profile or Gola handles of 45/30ºC even on J. Profiles.

- The joint between the Premium Acrylic sheet and the edge can be polished so that the joints are not noticeable.

These types of handles are trending on the market. On one hand, they follow the current standards of aesthetics. They are modern and elegant. On the other hand, they create more space in small rooms or transit areas, they make it possible to clean the area, and they prevent breakages or the maintenance problems of conventional handles.

These types of handles are trending on the market. On one hand, they follow the current standards of aesthetics. They are modern and elegant. On the other hand, they create more space in small rooms or transit areas, they make it possible to clean the area, and they prevent breakages or the maintenance problems of conventional handles.

By using edges of the same acrylic material (ABS/PMMA, the stability against the UV effect is higher than when using ABS edges and the finish is of a higher quality.

SERVICE AND FLEXIBILITY:

Shorter times and Smaller quantitiesAt Plasnor we are aware of the importance of reducing delivery times for our clients. That is why we offer the best and quickest delivery times on the market from receipt of the order to the manufacturing of the material. This makes it possible for our clients to reduce their stocks, and the financial costs that this entails, while carrying out their projects as quickly as possible.

Likewise, we are aware that in some cases it is difficult for our clients to fulfil the minimum order quantities. In this regard, we are flexible on the minimum order quantity (MOQ).

Service and flexibility, as well as personalised technical and commercial assistance for our clients are key elements of our value proposition.

SUSTAINABILITY AND RESPECT FOR THE ENVIRONMENT:

Recyclable, Non-toxicPlasnor´s ABS/PMMA Premium Acrylic sheets are free from materials that are toxic and harmful or dangerous to health in the case of combustion, such as PVC.

The plastic used in the production process of Premium Acrylic sheets is 100% recyclable and the waste generated in their manufacturing is reused in other applications, encouraging sustainability and environmental respect.

OPTIMAL UV AND CHEMICAL RESISTANCE:

Excellent level of colour stability against UV exposure and resistance to chemical agentsThe surface layer of PMMA of the Premium Acrylic sheets is one of the materials with best stability against sun exposure. Their use in indoor furniture guarantees the colour stability of the surfaces over the years.

In the laboratory tests carried out according to the standard ISO 4892-2, the performance of the colours is optimal.

With regard to chemical resistance, the sheets are not affected by contact with the most common products.

The chemical resistance of the sheets has been tested according to the standard DIN 68861/T1, without alterations.

EASY TO PROCESS:

With standard carpentry machineryThe Premium Acrylic sheets can be easily processed with the conventional tools used in the furniture industry. They enable easy machining or cutting, drilling and edging of boards.