At Plasnor we have our own laboratory and we produce our own colour concentrates or masterbatches, which enables us to be colour specialists. Our team of professional chemists in the laboratory is responsible for analyzing, studying and developing the colors that our customers demand from us by mixing materials, plastics, dyes, pigments and additives.

We thus guarantee reliability when it comes to maintaining the colour shades in successive batches of sheets, and over time. Also, we obtain great precision when it comes to developing new colours or (identically) reproducing any colour requested.

In order to measure the colour of the materials a colorimeter is used, which is based on three coordinates:

L: The lightness of the colour, from 0 to 100

A: How red or green the colour is

B: How yellow or blue the colour is

A formula combining these three coordinates will provide the end satisfaction level or delta number. The demands are strict, and we respond to them in order to maintain color in the following productions.

At Plasnor, we carry out different measurements of the delta colour, both during the production process and on the end product. That is why we can offer a 100% guarantee that the colour we give to our clients is the one that they have requested.

We initially create a masterbatch that ensures precision in the colour shade and its optimum distribution in the subsequent multilayer coextrusion process on sheets or reels.

Where are these coloured sheets used afterwards?

- The furniture sector:

We produce high gloss acrylic surface sheets for the furniture sector, which are highly valued in this market. This is our brand NORSAN HIGH GLOSS. Our clients use these ABS/PMMA (methacrylate surface) to cover wood panels and to manufacture wardrobe doors or kitchen furniture. Each client works with their own range of colours, therefore precision is crucially important and success batches must guarantee colour stability.

- Health sector:

We manufacture ABS/PMMA sheets for the health sector which are then turned into items such as baths, cabins, columns and shower trays and even SPAs. In the health sector the most frequently used colour range is that based around white. Each brand works with a specific shade of white, which normally corresponds to their brand image. At Plasnor we manage to provide each client with the specific shade of white they need.

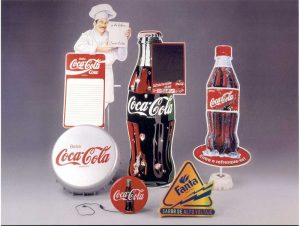

- POS Sector

In the point-of-sale advertising sector (or advertising displays) the colour is often the brand image, therefore it is essential to 100% respect the colour that the client requests. But, above all, the key is to be able to develop colours very quickly. Having its own laboratory enables Plasnor to meet the needs of each client in record time. For this sector, we manufacture using a polystyrene (PS or HIPS) sheet extrusion process, and the sheets are subsequently transformed using other processes such as thermoforming, machining and printing, for example.