THERMOFORMING TECHNOLOGY

Materials

The majority of thermoplastics may be used. They must be in sheet form (sheet or rolls).

Tools (Moulds)

They may be made of the following materials

- Aluminium: Undefined life cycle. For long series. Provides good finish for parts.

- Resin: Prototype phase. Short series.

- Wood: Practically in disuse today. Samples or short series.

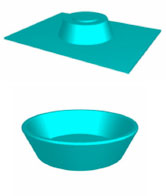

Thermoforming process

Consists of the following steps:

- Board extrusion

- Placement of board on the mould

- Heating

- Moulding by applying vacuum

PROCESS PHASES

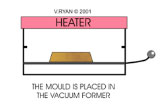

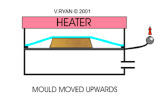

- Preparation

- The mould is placed in the thermoforming machine.

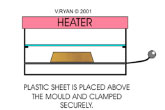

- Placement

- A plastic sheet (for example, ABS) is placed on the mould.

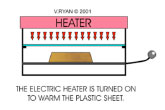

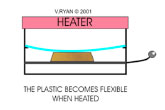

- Heating

- The plastic sheet is heated until it softens.

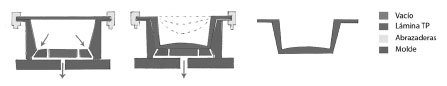

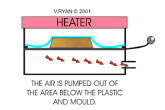

- Moulding

- Vacuum pressure is applied, and this removes all of the air under the plastic. The atmospheric pressure on the plastic makes it adapt to the mould.

- Cooling

- With an internal mould cooling circuit and fans, the plastic is cooled. Once sufficiently cooled, the vacuum is turned off.

- Removal from mould

- The plastic is removed from the moulding machine. The sheet has taken on the desired shape.

- Excess plastic is removed, and the part remains clean.