01. WHAT KIND OF MACHINERY IS NEEDED TO LAMINATE OUR NORSAN HIGH GLOSS?

The use of PUR hot glue laminating lines is absolutely mandatory.

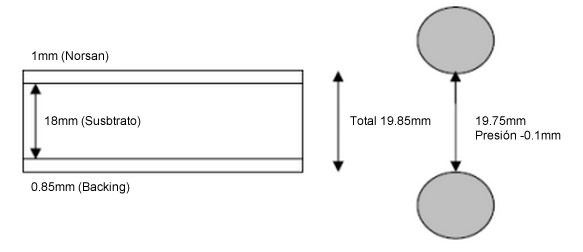

Here you can see a basic sketch of a production line.

02. HOW MUCH PRESSURE SHOULD BE USED WHEN APPLYING NORSAN HIGH GLOSS TO THE MDF?

Optimum pressure depends on the substrate used (MDF / Chipboard/ plywood) as well as the amount of glue applied. Normally, the higher the pressure the greater number of defects that can appear on the surface, since the acrylic sheet photocopies the imperfections that the board’s surface may have. On the other hand, the higher the pressure, the higher the quality of the sheet’s pasting on the MDF.

Therefore, we clearly must seek a middle ground. Our clients press with force between 0.1 mm and 0.3 mm

03. WHAT TYPE OF GLUE NEEDS TO BE APPLIED?

The glue must be PUR. Do not attempt to apply other glues. Our experiences has taught us that they never work properly. We recommend the following references: Kleiberit ref. 709.3, Henkel ref. QR4663 or Jowat 609.20. Any other hot PUR glue should work well. The glue should reach a temperature of up to 140ºC in order to be sufficiently liquid. The roller by means of which the glue is applied should be at a temperature of about 125ºC.

04. WHY DO SOME NORSAN HIGH GLOSS SHEETS APPEAR IRREGULAR ON THE PALLET?

Acrylic methacrylate is a thermoplastic, and waves may sometimes appear on the sheet during the extrusion process. These waves do not affect the quality of the board after lamination, since when the sheet is pasted, the waves disappear.

05. HOW ARE THE NORSAN HIGH GLOSS LAMINATED BOARDS EDGED?

There are companies who are specialised in manufacturing ABS edging on the market. Our recommendation is Dollken or Rehau, since they offer our entire colour selection in their catalogue.

06. IS IT POSSIBLE TO POST-FORM OUR NORSAN HIGH GLOSS?

It is possible to post-form our product, and with the appropriate machinery we can attain a minimum radius of 1.5mm.

ABS/PMMA is a thermoplastic, which means that its shape can be modified if adequate heat is applied. The most important aspect is applying heat right at the angle. The heat applied should be greater than 110ºC.

07. ONCE THE NORSAN HIGH GLOSS IS GLUED ON THE MDF, WHEN WILL WE BE ABLE TO CUT THE BOARD?

We recommend waiting at least 24h to cut the board, until the glue has dried and stabilised.

08. IS IT POSSIBLE TO POLISH SMALL SCRATCHES? IF SO, WHICH PRODUCT SHOULD I USE?

- Small marks and scratches can be polished, since the surface is acrylic. However, deeper scratches cannot be removed, since the thickness of the methacrylate layer is only 0.1mm, approx.

- Any polishing product will work correctly. For example, products used to polish vehicle bodies are appropriate and can be found at any vehicle repair shop.

09. WHAT TYPE OF CLEANING PRODUCT CAN BE USED TO CLEAN THE SURFACE OF A NORSAN HIGH GLOSS DOOR?

We recommend cleaning the surface with a microfiber cloth and water and liquid soap. Cleaning agents with anti-static properties are appropriate for preventing static electricity.

We recommend a product called Vuplex, a product specifically for cleaning plastic.

10. WHAT TYPE OF CLEANING PRODUCT SHOULD BE USED TO CLEAN LEFTOVER GLUE REMAINING ON A NORSAN HIGH GLOSS DOOR?

When removing the protective film, it is important to clean leftover adhesive from the sheet’s surface. Otherwise, it may appear that the surface was scratched in handling, when it is actually leftover glue.

Our recommendation to clean leftover glue is to use damp microfiber cloths, carefully cleaning the surface. This simple procedure increases our sheet’s scratch resistance, as well as surface shine.

In this case, we also recommend using Vuplex cleaner.

11. ARE THERE ANY SPECIAL REQUIREMENTS FOR STORING NORSAN HIGH GLOSS (HUMIDITY, TEMPERATURE, ETC.)?

There are no special requirements for storing our product. The only suggestion that we have is that the sheets must be glued to the board before 6 months, and no weight greater than 3Ton should be placed on the pallet.